Road access to Chatter Creek is first by a 30 km drive on the TransCanada Highway to Donald, the terminus of the old (now disused) Big Bend Highway. From Donald, a logging road runs north, along the eastern shore of

Kinbasket Lake, a portion of the Columbia River valley flooded by the Mica Dam. The road skirts the end of

Bush Arm, where the lake protrudes to the east into the Rocky Mountains. Part way along the northern shore of Bush Arm, the logging road is intercepted by the Chatter Creek access road, a 17 km track that winds its way up valleys to the Chatter Creek lodge site. The distance from Golden to the bottom of the Chatter Creek road is about 90km.

The Chatter Creek access road presents a significant challenge. It is very rough. Built as a summer logging road, it was intended to be temporary and proper crowning and drainage was not part of its construction. In the spring, large sections of the road are deep bogs. As the road dries out during the summer, a crust forms over the bogs, usually thick enough to support 4x4 vehicles, bulldozers and excavators. In the spring, before the road dries out and a sufficient crust forms over the bogs, the road is very slippery, unstable and will not support heavy loads.

In order to meet the short building schedule, the new sawmill and the mobile crane to be taken to the building site long before the access road dried out. A three-day effort ensued to haul the equipment up the short distance. A 4x4 1-ton truck carrying most of the sawmill was pulled by a D4 bulldozer and the mobile crane was pulled and pushed, as needed, by a tracked excavator. A Hummer was used as a support vehicle. It was slow, with the crane's 6ft diameter wheels often sinking in the mud to their axles.

In the end, the effort was successful. The mill was assembled and went into immediate service and the crane's boom was assembled, ready for work.

Click here for more pictures and information about

Life on the Chatter Creek Road

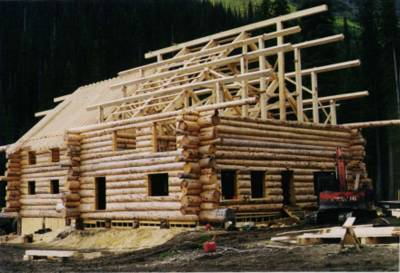

Vertebrae and Solitude Lodges at Chatter Creek Cat Skiing. The young owners of Chatter Creek built their first large 9000+ sq. ft. mountain lodge in 2002 and a second in 2004. The photo above shows the two lodges with a brand new entryway constructed in 2005.

Vertebrae and Solitude Lodges at Chatter Creek Cat Skiing. The young owners of Chatter Creek built their first large 9000+ sq. ft. mountain lodge in 2002 and a second in 2004. The photo above shows the two lodges with a brand new entryway constructed in 2005.